The automotive industry is making strides forward in the 21st century. As technology continues to advance, lasers have become a powerful tool for improving efficiency and safety across all aspects of vehicle production.

This article will explore four ways that lasers are pushing this sector into a brighter future: from precise cutting techniques to advanced scanning capabilities. Well also look at how these new advancements can help reduce cost and environmental impact while increasing overall performance.

With laser-based technologies now being used by leading automakers, its clear that the future of transportation looks bright indeed!

Table of Contents

Laser Technology Enhancing Automotive Efficiency

The auto industry is quickly realizing the potential of laser technology to increase efficiency and reduce costs. By incorporating lasers into various facets of production, automakers are able to create lighter, more fuel-efficient vehicles that can go faster and farther while using less energy than ever before.

Laser cutting is one example of how manufacturers have been able to use precise measurements in order to craft metal parts with near perfect accuracy. Additionally, lasers are allowing engineers to design systems that will help monitor a car’s performance as it travels down the road so they can detect any issues right away without having to wait for the vehicles return from a test drive or other diagnostic procedure.

Lasers also enable automakers to precisely measure and adjust tire pressure during manufacturing processes which improves fuel economy significantly. Finally, laser welding has allowed for stronger bonds between components like steel frames and doors which makes cars safer while reducing weight at the same time resulting in improved performance on the road.

The bright future is here: laser technology is revolutionizing automotive engineering by increasing efficiency, safety standards, and overall cost savings across the entire industry!

Improved Automotive Manufacturing Processes

Lasers have revolutionized the automotive industry, allowing for improved processes and greater efficiency. Automotive manufacturers can now take advantage of precise laser technology to cut production times, reduce costs, and produce higher quality parts.

Laser cutting is faster than traditional methods due to its ability to accurately make cuts without requiring repositioning or adjustments between operations. This same accuracy also enables automakers to create intricate shapes and designs that would be impossible with traditional tools.

Additionally, lasers are able to work on a variety of materials including plastic and metal components as well as coatings such as paint or powder coating. With these capabilities in hand, automakers are leveraging laser technology across the entire manufacturing process from prototyping right through mass-production runs at scale.

By using lasers for improved automotive manufacturing processes they are creating better products while saving time and money – a winning combination!

Increased Safety

The automotive industry is rapidly advancing towards a future of increased safety. Laser technology has been instrumental in this process, providing precise measurements and enhanced vision capabilities that can detect even the slightest changes in surrounding environments.

Lasers are being used to create safer automated driving systems, as they allow for better identification of obstacles and other vehicles on the road. Additionally, laser assisted parking systems have enabled cars to park with greater precision while avoiding collisions or dings on other vehicles nearby.

As lasers continue to be integrated into vehicle designs, the automotive industry will move closer towards a future with fewer accidents due to improved safety measures such as lane departure warnings and blind spot detection systems powered by laser technology.

Expanding Possibilities for Autonomous Vehicle Innovation

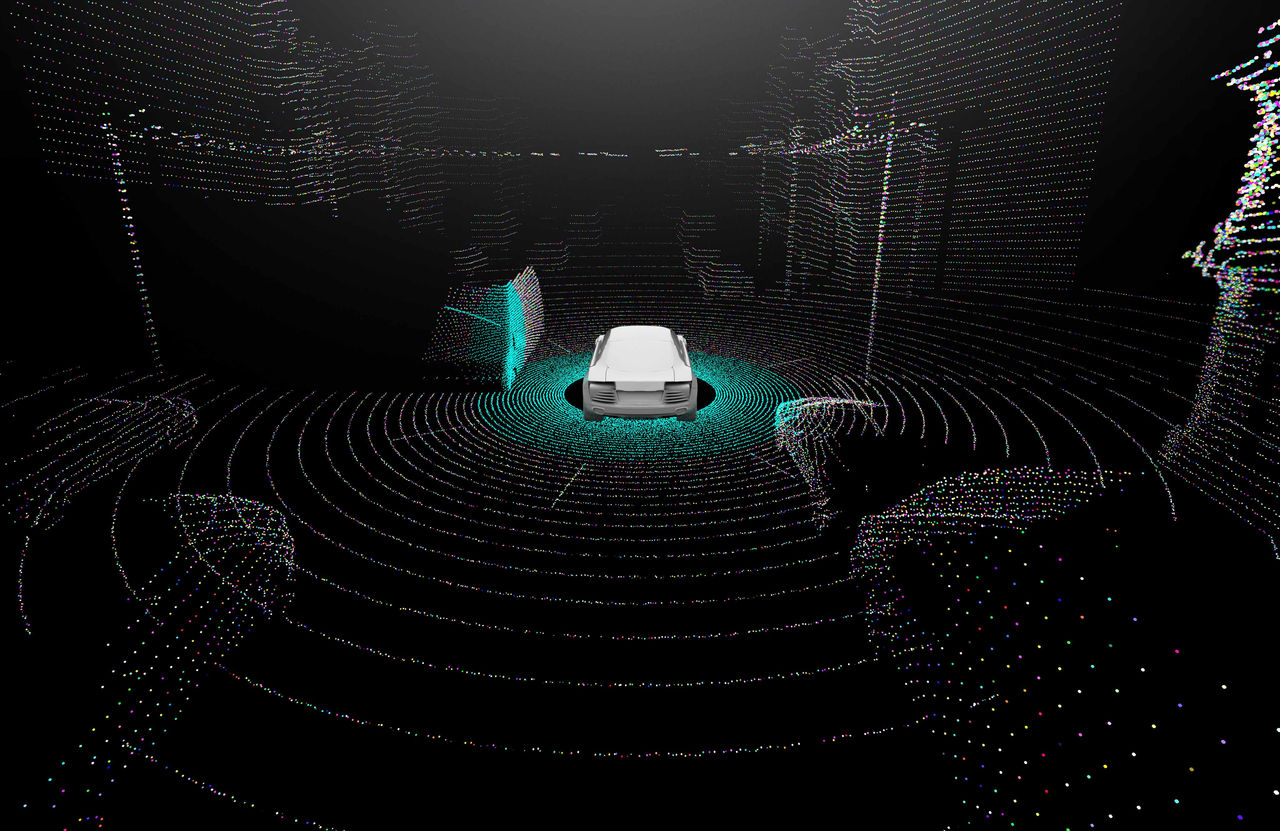

The potential for autonomous vehicles is rapidly expanding as lasers are being utilized in unique and innovative ways. Laser-based technologies enable the automotive industry to create efficient, reliable, and cost-effective systems that can be used to increase safety features on cars, optimize navigation systems, and even enhance vehicle performance.

With laser technology at its core, the possibilities of self-driving cars become increasingly realizable. From improved parking capabilities to precise mapping abilities; from enhanced night vision solutions to remote monitoring; these advancements have already begun revolutionizing the industry with no signs of slowing down anytime soon. As we look towards a bright future for automated driving solutions, its clear that lasers will continue playing an integral role in advancing the boundaryless potential of autonomous vehicles.

Conclusion

The automotive industry is constantly evolving, and lasers are playing a major role in driving the industry forward.

The automotive industry is constantly evolving, and lasers are playing a major role in driving the industry forward.

From laser cutting to high-precision welding, lasers offer an array of advantages that cannot be achieved with traditional tools. Moreover, laser marking machines can provide automakers with permanent markings on parts and components that can withstand harsh environments. As lasers continue to advance, they will become even more integral for carmakers who need to meet tight deadlines while ensuring quality products.

This technology has already proven itself as one of the most efficient ways to produce cars today – and its future looks even brighter!